Certifications

We claim to create high-quality and technically impeccable end products that meet the high requirements of our customers. That is why we also attach great importance to standardized and standard process sequences that we check and have certified at regular intervals. Besides the quality management system, which we operate in accordance with ISO 9001, we also comply with DIN EN 1090 with delivery class of EXC3 and international norm DIN EN ISO 3834-2. In addition to that we own the transfer authority from TÜV SÜD with the material registering mark AD-2000.

Quality management system according to ISO 9001

The quality management standard ISO 9001 is the most widespread and most important standard in quality management. We aspire to comply with this standard and comply with the ISO 9001 Standards.Our internal operating processes and sequences are continuously checked and developed. In this way we can always get better. Hidden potentials are uncovered and fully exploited. The result is an optimum and efficient run through our customer orders – from the order via production planning and production to the punctual delivery.

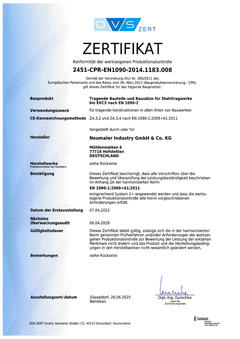

Certification in accordance with DIN EN 1090

The European DIN EN 1090 regulates the conformity assessment, in-house production control, supplier certification as well as CE identification for loadbearing steel and aluminium components which will be used as parts. We hold the authority for loadbearing components and assemblies for structural steel work up to EXC3 in accordance with EN 1090-2 as well as welding of structural steel with a delivery class of EXC3 in accordance with EN 1090-2.

Certification in accordance with DIN EN ISO 3834-2

The international standard series DIN EN ISO 3834 specifies welding-related quality requirements for manufacturers and regulates the principles for the quality assurance of fusion-welded components and constructions. We also hold DIN EN ISO 3834-2:2006 which includes comprehensive quality requirements for an application range of: manufacturing of products such as equipment, machinery, commercial vehicles and steel constructions.

Transfer authorisation of material identifications according to AD-2000

We have the authorisation from TÜV Süd to transfer material identifications according to AD-2000 instructions HP0. This authorisation is the basic requirement above all in the case of load-bearing parts resp. sheet metal constructions or also in the manufacture of pressure vessels. The transfer authorisation enables us to record and document completely the materials used and gives us the authority to carry out transfer of identification of material designations.