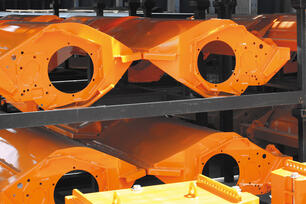

Surface finishing: Clean surfaces

Various procedures and machines are available for the finishing of sheet metal surfaces at our company, guaranteeing a smooth and clean surface of the cut parts.

With a Weber multi function machine we can not only deburr, but also chamfer and descale the cut edges resp. polish the surfaces.

A sandblasting unit with airless blasting-continuous blasting procedure supplements our service capacity in the field of surface reworking.

Surface finishing performance data

Machine: 1 x Weber grinder

Procedure: Grinding, deburring, chamfering, descaling

Working area: 6,000mm x 1,500mm

Material thickness: 1mm to 100mm

Machine: 1 x Sandblasting unit

Procedure: Airless blasting-Continuous blasting

Working area: 1,500mm x 15,000mm

Material thickness: 1mm to 650mm

The advantages of a good processing of the surfaces lies in a lower risk of injury during subsequent handling or further processing. A clean finishing of surfaces is especially important among other things in the case of cut parts that are varnished afterwards. By chamfering the edges for example, a corresponding structure of thicknesses of layers is possible, offering nearly the same service life as the varnish on the surface. If the cutting areas were descaled in addition, the perfect mechanical adhesion is also guaranteed there.

This might also be of interest to you

-

Laser cutting

We use high-performance Trumpf laser cutting systems to cut sheet metal with the utmost precision and top quality. -

Surface refinement

Surface finishing of gas-cutting parts with powder coating, phosphatising, CED electrophoretic painting, wet painting, chromising, anodizing, electrogalvanizing, hot galvanizing.