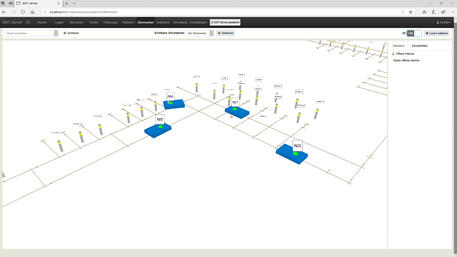

AGV FS400 Factory Shuttle – Compact and Automated Guided Vehicle (AGV)

Compact, manoeuvrable and customised – the Factory Shuttle FS400 Automated Guided Vehicle (AGV) is a versatile AGV and offers everything required for modern and efficient factory automation. Due to a standardised modular principle, the AGV Factory Shuttle FS400 can be configured specifically to the customer’s processes and load carriers. This way the internal material flows can be automated in the best possible way, costs can be saved and safety can be increased.

AGV Factory Shuttle FS400 at Grammer in Zwickau

The Factory Shuttle AGV is a transport shuttle and is driven in the base by a 2-way steering system. The navigation and orientation of the AGV is done by geonavigation / contour navigation (other navigation possible). Hybrid navigation (a combination of different navigation modes in the AGV) is also possible. The FS400 Automated Guided Vehicle is powered by a lithium iron phosphate (Li-FePo4) battery with an automatic charging function. PL-d laser scanners are used in the AGV transport shuttles to ensure safe driving and maximum personal protection. In addition, the FS400 AGV has other safety features and lighting systems such as directional flasher and BlueSpot.

The payloads of the AGV FS400 series ranges from 400 kg to max. 3,000 kg. The integrated electric lifting gear achieves a lifting height of 100 mm in the standard version. Various load handling devices are available for picking up and delivering loads, such as forks or conveyor technology for picking up/delivering from or onto roller conveyors.

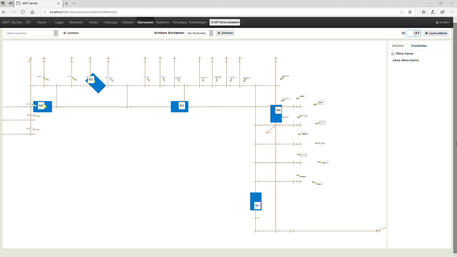

The FS400 AGV is managed and controlled via intuitive and user-friendly management software with API and graphical user interface. This can be used to control and manage transport requests. Capacities, various statistics and battery statuses can quickly and easily be checked using the system. Routes as well as sources/lowering can also be changed via the management software.

The Automated Guided Vehicle FS400 at a glance

Drive and power:

- 2-way drive steering system for precise driving operation

- Driving speed max. 1.2 m/s

- Li-FePO4 rechargeable battery with automatic charging function

- Optional induction charging function

- Manual operation via joystick mode

Payload and load carrying capacity:

- Different payload versions from 400 kg to 3,000 kg

- Electric lifting gear with up to 100 mm lifting height and integrated overload protection

- Individual load-bearing superstructures

Communication and operation:

- Information display with battery, status and safety indicator

- WiFi connection

- Touch displays for easy job initiation

- Intuitive and user-friendly management software with API and graphical user interface

- Geo navigation / contour navigation (other navigation or hybrid navigation possible

- Personal security system with PL-d laser scanner in the main direction of travel and PSA bumper when reversing

- Safety monitoring with different safety zones

- BlueSpot and other lighting (option)

Further equipment and options:

- Stationary and mobile transfer stations

- Increase in driving speed

- Customised adaptation of the size

- Expansion of the safety sensor system

- Communication boxes for external signals/actuators such as gates or fire alarm systems

- Service-friendly, low-maintenance and robust metal construction

- Further options and application-specific adaptations possible upon request

References indoor AGVs and outdoor AGVs

This might also be of interest to you

-

Autonomous (outdoor) tugger train: Factory Train FT600 and FT900

Fully automated tugger train for internal driverless transport in indoor and outdoor areas. -

Automated high bay warehouse

Automated high bay warehouse with fully automated narrow-aisle stackers, conveyor technology and IT connection. -

Neuamier demonstration centre for automated intralogistics

Experience automated intralogistics live in real operation at the Neumaier demonstration centre.