Conveyor technology and order picking

With the Neumaier narrow-aisle solution, order picking productivity at the high bay is increased by 35%. This is made possible by:

- Sophisticated conveyor technology/processes with conveyor sections and roller conveyor trolleys.

- Elimination of forklifts and other floor conveyors in the order picking zone

- Fixed and fully equipped order picking workstations

- Multiple source sinks for parallel storage and retrieval

Lengthways serving process with multiple source sinks

Several source sinks are arranged lengthways of the high-bay racking. The load carriers are automatically conveyed into the high bay aisle via pass-throughs and can be picked up by the narrow-aisle stacker and stored or conveyed onwards. The lengthways serving process not only optimises the process speeds and thus increases the handling performance, but also offers many other advantages compared to the usual front-side serving process:

- No dangerous and time-consuming manoeuvring of narrow-aisle forklifts outside the high bay racking in the order picking area

- Short travelling distances of the load carriers via direct pass-throughs

- Several source sinks for time-saving storage and retrieval

- Operation of the high bay racking from both sides via the arrangement of source sinks on both long sides

- Savings on additional order picking and storage equipment

Ergonomic, efficient and safe order picking zones

The order picking workstations are fully equipped and firmly defined. The employee's working radius is clearly defined, handling machines such as high stacker or forklifts are no longer necessary. Order picking is carried out exclusively via special roller conveyor trolleys and conveyor technology. Each picking workstation has full IT connection to the ERP and WMS.

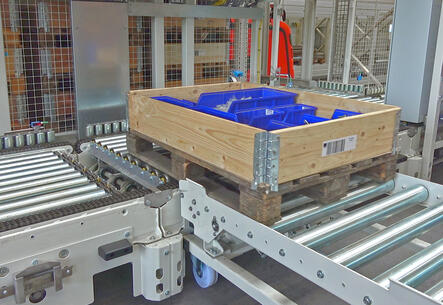

Conveyor technology and roller conveyor trolleys

Load carriers are transferred to the conveyor line in the order picking zones via special and individually movable roller conveyor trolleys. The conveyor line, which is permanently installed along the entire length of the high bay racking, can be configured with variable functional sequences according to needs and requirements.

During the storage process, each load carrier is checked and scanned fully automatically: Type, weight, contours, offset, barcodes and photographically documented. The storage of the load carrier in the high bay is done according to priority, picking affiliation and frequency.

Before the load carrier is picked up and stored by the narrow-aisle stacker, it is automatically aligned by the conveyor system. This guarantees fast and accurate pick-up by the narrow-aisle stacker.

Conveyor and order picking technology at a glance:

- 35% higher order picking productivity

- Reduction of picking/storage equipment

- Fully equipped and firmly defined order picking zones

- Roller conveyor trolleys with docking function and backstop

- Partially to fully automated functional sequence of the conveyor line

- Automatic restacking of the load carriers on the conveyor line

- Automatic centring and alignment of the load carriers before the storage process